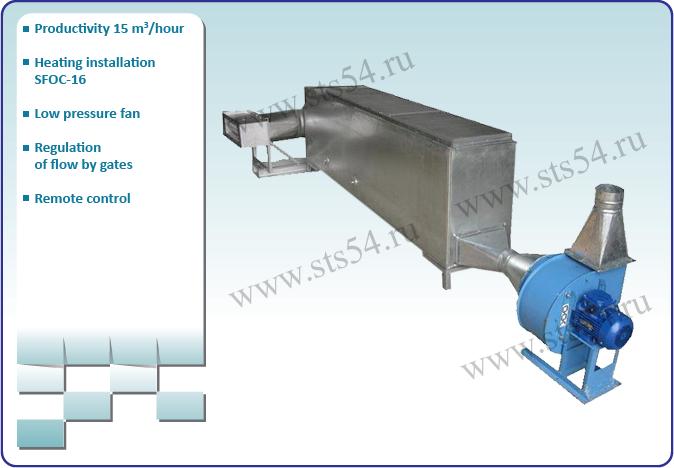

Drying set for manufacture of low density foamed plastic

| Weight, kg | 150 |

| Staff required | 1 person |

| Overall dimensions, mm | 4230x715x680 |

Drying set is designed for drying and oxygenation of previously expended granules before they are dispatched to the ageing bunker. The installation is used in the manufacture of low density polystyrene (М15) for the quality improvement.

Design and operating principle:

Structurally the drying set consists of five segments:

- SFOTS 16 Electric radiator.

- Drying unit case.

- Galvanized passage.

- Radial ventilator of low pressure.

- D125 Outlet fitting.

The dryer case has butterfly gates for regulation of heated air flow.

Air heated to 40-50oС is continuously fed to the thermal treatment body. Previously expended granules get inside the drying unit through the loading hatch where they are exposed to air-thermal treatment. This process leads to the internal pressure stabilization and hardening of granules’ outer walls.

Falling into the dryer expended granules should be in continuous motion in the direction of the pneumatic suction fan. It is necessary to regulate the heated air flow by turning gates of the dryer case, so the granules are not accumulated and stagnated.

After that the granules get inside the suction fan through the galvanized passage. Then by force of air flow they are moved to the pneumatic system through the outlet fitting.

Specifications:

Parameter |

Level |

|

Capacity during primary foaming of granules, m3 /hr |

15 |

|

ower consumption max, kW |

17 |

|

Power of electric radiator SFOTS16-250, kW |

15 |

|

Power of radial ventilator electric motor , kWt |

1,1 |

|

Max air discharge temperature, t°С |

50 |

|

Supply voltage, V |

380 |

|

Frequency, Hz |

50 |

|

Max wind resistance, Pa |

400 |

|

Temperature difference of air-in and air-out, t°С |

30 |

|

Max weight, kg |

150 |

|

Operating temperature, t°С |

+5 +40 |

|

Dimensional specifications, mm

Length |

4230 715 680 |

|

Climatic modification |

YЗ(GOST15150) |

|

Operational mode-continuous |

(S1) |

|

Maintenance staff, persons |

1 |

+7 913-923-66-02

+7 913-923-66-02