Advantages and disadvantages of aerated concrete

Before looking into the advantages and disadvantages of aerated concrete, we need to mention that aerated concrete can be of the two types: non-autoclave and autoclave hardening. Let’s look through the difference between autoclave and non-autoclave aerated concrete.

Non-autoclave aerated concrete hardens under standard conditions (in thermal treatment chambers). Such manufacturing technology ensures minimum expenses on equipment and electricity.

The raw materials for manufacturing are: cement, mineral aggregate (sand, fly ash, dolomite powder), water, gas-forming agent (based on aluminum powder), and modifying additives.

Autoclave concrete results from hardening aerated concrete in autoclaves at the temperatures ranging 120 and 200оС and at the pressure of P=1.4 MPa The raw materials for manufacturing aerated concrete are: lime, cement, mineral aggregate, water, foam-forming agent (based on aluminum powder), and modifying additives. Thanks to lime, the quantity of cement used is lower, so, the cot of raw materials for manufacturing autoclave aerated concrete is lower than that of the non-autoclave one. Autoclave hardening ensures better strength for aerated concrete if compared to the non-autoclave one.

1.Economical efficiency of construction. The low cost of materials, as well as the large dimensions of blocks which have less weight ensure construction cost reduction.

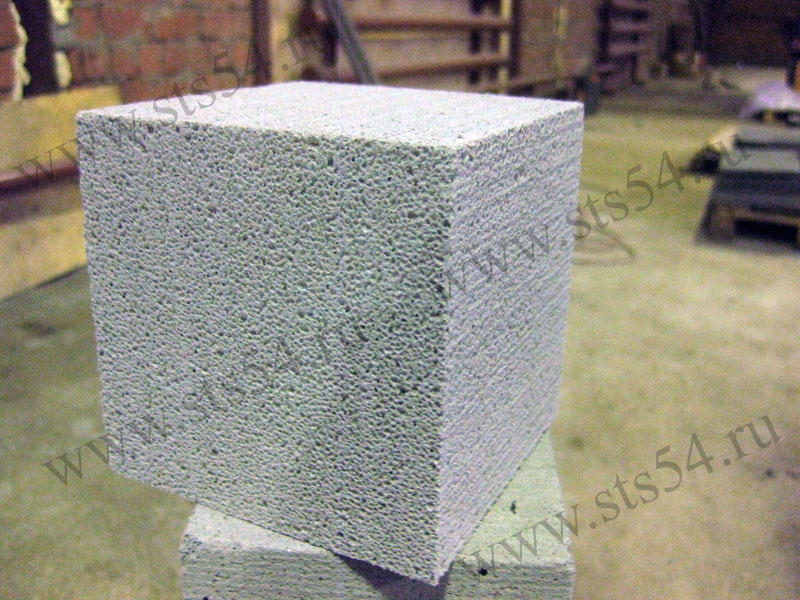

2.Low density, low thermal conductivity. Aerated concrete blocks have the density between 400 and 800 kg per cu.m and the thermal conductivity coefficient ranging between 0.1 and 0.21 W/(m*оС), that is why they are light and warm.

3.Good acoustic protection. Thanks to its porous structure, aerated concrete ensures soundproofing 10 times better than a brick wall of the same thickness.

4.Fire safety. Aerated concrete is a non-combustible, fire-resistant material, has the first class of fire-resistance, which exceeds the one of ordinary concrete.

5.Vapor permeability. Thanks to its porous structure, aerated concrete has good vapor permeability. The vapor permeability coefficient is between 0.23 and 0.4 mg/(m*h*Pa).The houses made of aerated concrete “breathe”, and the microclimate inside is comfortable.

6.Environmental friendliness. Aerated concrete contains natural, environmentally clean ingredients. The material does not release any harmful substances, does not age and is not prone to decompose. The background radiation is 9 to 11 µR/h. For reference: the average background radiation in Moscow is 13 to 15 µR/h.

Autoclave aerated concrete has another disadvantage - due to high water absorption, it is required to eliminate environmental impact on the material, i.e. Cover autoclave aerated concrete with plaster, decorative facades, etc.

Non-autoclave aerated concrete hardens under standard conditions (in thermal treatment chambers). Such manufacturing technology ensures minimum expenses on equipment and electricity.

The raw materials for manufacturing are: cement, mineral aggregate (sand, fly ash, dolomite powder), water, gas-forming agent (based on aluminum powder), and modifying additives.

Autoclave concrete results from hardening aerated concrete in autoclaves at the temperatures ranging 120 and 200оС and at the pressure of P=1.4 MPa The raw materials for manufacturing aerated concrete are: lime, cement, mineral aggregate, water, foam-forming agent (based on aluminum powder), and modifying additives. Thanks to lime, the quantity of cement used is lower, so, the cot of raw materials for manufacturing autoclave aerated concrete is lower than that of the non-autoclave one. Autoclave hardening ensures better strength for aerated concrete if compared to the non-autoclave one.

The following advantages of autoclave and non-autoclave concrete can be identified for the construction:

1.Economical efficiency of construction. The low cost of materials, as well as the large dimensions of blocks which have less weight ensure construction cost reduction.

2.Low density, low thermal conductivity. Aerated concrete blocks have the density between 400 and 800 kg per cu.m and the thermal conductivity coefficient ranging between 0.1 and 0.21 W/(m*оС), that is why they are light and warm.

3.Good acoustic protection. Thanks to its porous structure, aerated concrete ensures soundproofing 10 times better than a brick wall of the same thickness.

4.Fire safety. Aerated concrete is a non-combustible, fire-resistant material, has the first class of fire-resistance, which exceeds the one of ordinary concrete.

5.Vapor permeability. Thanks to its porous structure, aerated concrete has good vapor permeability. The vapor permeability coefficient is between 0.23 and 0.4 mg/(m*h*Pa).The houses made of aerated concrete “breathe”, and the microclimate inside is comfortable.

6.Environmental friendliness. Aerated concrete contains natural, environmentally clean ingredients. The material does not release any harmful substances, does not age and is not prone to decompose. The background radiation is 9 to 11 µR/h. For reference: the average background radiation in Moscow is 13 to 15 µR/h.

Now, let’s look through the disadvantages of aerated concrete:

Very expensive equipment is required for manufacturing autoclave aerated concrete, as well as high power consumption and large production facilities. That is why low-volume production of blocks is not economically advantageous. This is the key disadvantage of autoclave aerated concrete. In this case, manufacturing non-autoclave aerated concrete seems more attractive for small business.Autoclave aerated concrete has another disadvantage - due to high water absorption, it is required to eliminate environmental impact on the material, i.e. Cover autoclave aerated concrete with plaster, decorative facades, etc.

+7 913-923-66-02

+7 913-923-66-02