Block molding

| Weight, kg | 1800 |

| Size of the resulting block, mm | 2000 * 1000 * 500 |

| Steam flow, kg/hr, max | 180 |

| The volume of the resulting block, m3 | 1 |

| Density of the resulting block, kg/m3 | 10 ... 40 |

| Steam pressure, MPa | 0.3 |

| Overall dimensions, mm | 2302 * 800 * 1300 |

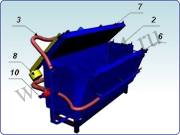

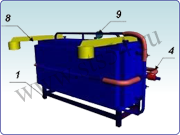

A block molding is carried out in block-cassettes by a heat-stroke method. Foamed and matured polystyrene granules are delivered from the maturing bin by pneumatic transport system, or manually to the cassette cavity. The top cover -7, fitted with a counterweight -8 is locked, and braced to the framework with screw locks or wedges. Stem from the steam line through a flange -10 is fed through steam pipes -3, -4, -5 into the steam jacket of the walls and the lid of the cassette, and throung a lot of holes with diameter of 1 mm. enters the cavity of the cassette. Under the action of the steam polystyrene pellets froth and sinter to a single monolithic bloc during 3-4 min. The pressure in the jacket is controlled by a manometer -9. After that, the air is supplied to the shirt. It removes steam and cools the resulting block. At the end of the cooling process the locks on the walls are opened, the top cover -7 is lifted, the side cover -6 is moved 30 degrees aside, the side wall -2 is opened, and the resulting block is removed, and left for curing for 1 day. When working with a horizontal block- cassette the whole process is exactly the same, only the foam polystyrene block is removed not from the side, as at the vertical one, but squeezed down by the air feed into the shirt of the top cover. The upper and lower covers are equipped with counterweights, and are fixed to the cassette framework with screw clamps, or wedges.

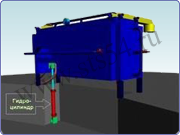

Our company also supplies block- cassettes with hydraulic unloading. The block ejection is made by using hydraulic cylinders installed in the bottom of the cassette in assembly holes. It makes the manufacturing process much easier, minimizes manual labor and increases the production culture. This cassette can be additionally equipped with control panel and oil station that allows you to manage the process of block molding from a remote control console.

+7 913-923-66-02

+7 913-923-66-02