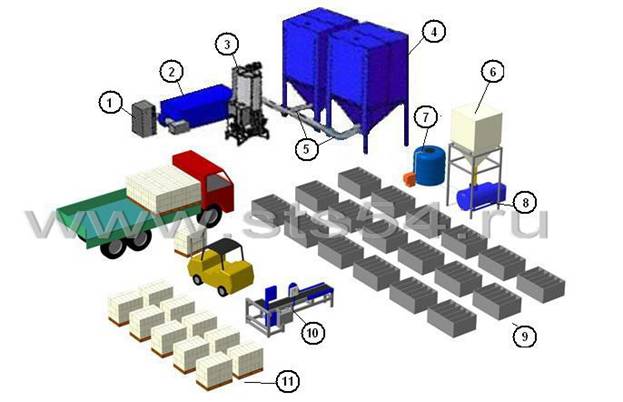

(capacity 20m3 per shift)

1. Steam generator

2. Dryer for EPS granules

3. PND-500 Automatic Pre-Expander (EPS Machine)

4. Ageing bunkers

5. Pneumatic system

6. Volumetric batcher of polystyrene granules

7. Water meter

8. RS-1000 Mixer

9. Moulds FM-1,47 m3

10. RK-3 Cutting set

11. Storage area for finished product

|

# |

Item |

Q-ty |

|

Sector of EPS foaming

|

||

|

1 |

PND-500 Pre-Expander (N - 3,3kW) |

1 |

|

2 |

PGES-50 Steam generator (N – 35 kW, 50 kg/hour) |

1 |

|

3 |

Dryer for EPS granules (N – 3 kW) |

1 |

|

4 |

Ageing bunker for EPS granules 40 m3 (it is possible to provide schemes for individual processing) |

3 |

|

5 |

Pneumatic system (N – 3 kW) |

1 |

|

Mixing sector

|

||

|

1 |

Volumetric batcher of polystyrene granules 1 m3 (V – 1,0 m3 ,N – 12 kW) |

1 |

|

2 |

RS-1000 mixer of polystyrene concrete (with embedded gerotor pump) |

1 |

|

Thermal treatment sector Thermal treatment cases are made by customer according to the project

|

||

|

Sector of polystyrene concrete mass sawing

|

||

|

1 |

RK-3 Cutting set for sawing of mass on blocks of definite sizes + mass gripper (N – 3 kW) |

1 |

|

2 |

Mould for concrete filling (V – 0,84 m3) (it is possible to provide schemes for individual processing)* |

24 |

* Final cost is determined after the stage of design in view of a placement.

Area of production site required min - от 300 m2

Temperature indoor min +15, +200 С

Electric power required 30-50* kW/hr

Water supply required.

Staff required – 4 persons, technologist/supervisor – 1 person.

|

Additional services

|

||

|

1 |

Visit of our technologist for equipment adjustment, proportioning, development of processing methods for make-up of polystyrene concrete and foam concrete using raw materials of the Customer, and also staff training |

By agreement |

|

List of additional equipment and materials for polystyrene concrete blocks’ production

|

||

|

# |

Item |

Q-ty |

|

Special vehicles |

||

|

1 |

Automated forklift (2-3tons) |

1 |

|

Additional equipment |

||

|

2 |

Balanced ventilation system |

1 |

|

3 |

Stocking hydraulic carts |

1 |

|

4 |

Household equipment, tools |

|

|

Other |

||

|

Consumption per month (25 work. days) |

||

|

5 |

Pallets for blocks stacking (reusable), pcs. |

500 |

|

6 |

Machine for strapping with polypropylene type, 1 pc. |

--- |

|

7 |

Polypropylene string, m |

7000 |

|

8 |

Wrap tape, m |

15000 |

Material consumption (polystyrene concrete).*

|

Mark by average density |

D 200 |

D 300 |

D 400 |

D 500 |

||

|

Material consumption |

Cement, t |

1 m3 |

0,2 |

0,25 |

0,35 |

0,4 |

|

Shift |

4 |

5 |

7 |

8 |

||

|

Polystyrene granules, m3 |

1 m3 |

1 |

1 |

1 |

1 |

|

|

Shift |

20 |

20 |

20 |

20 |

||

|

Admixture, kg |

1 m3 |

0,6 |

0,5 |

0,4 |

0,3 |

|

|

Shift |

12 |

10 |

8 |

6 |

||

Material consumption (foamed concrete).*

|

Mark by average density |

D 450 |

D 500 |

||

|

Material consumption |

Cement, t |

1 m3 |

0,43 |

0,45 |

|

Shift |

17,2 |

18 |

||

|

Foaming agent, kg |

1 m3 |

0,9 |

0,8 |

|

|

Shift |

36 |

32 |

||

* Mixes can be corrected in view of the Customer’s raw materials’ peculiar properties.

+7 913-923-66-02

+7 913-923-66-02